Fizeau Laser Interferometry for Precision Engineering and ManufacturingImagine being able to measure distances with incredible precision, down to a fraction of a nanometer. That's the power of laser interferometry! Whether you're involved in manufacturing, research and development or any industry that requires ultra-precise measurements, it's crucial to understand how laser interferometers work and their potentialities. |

|

|

Technologies |

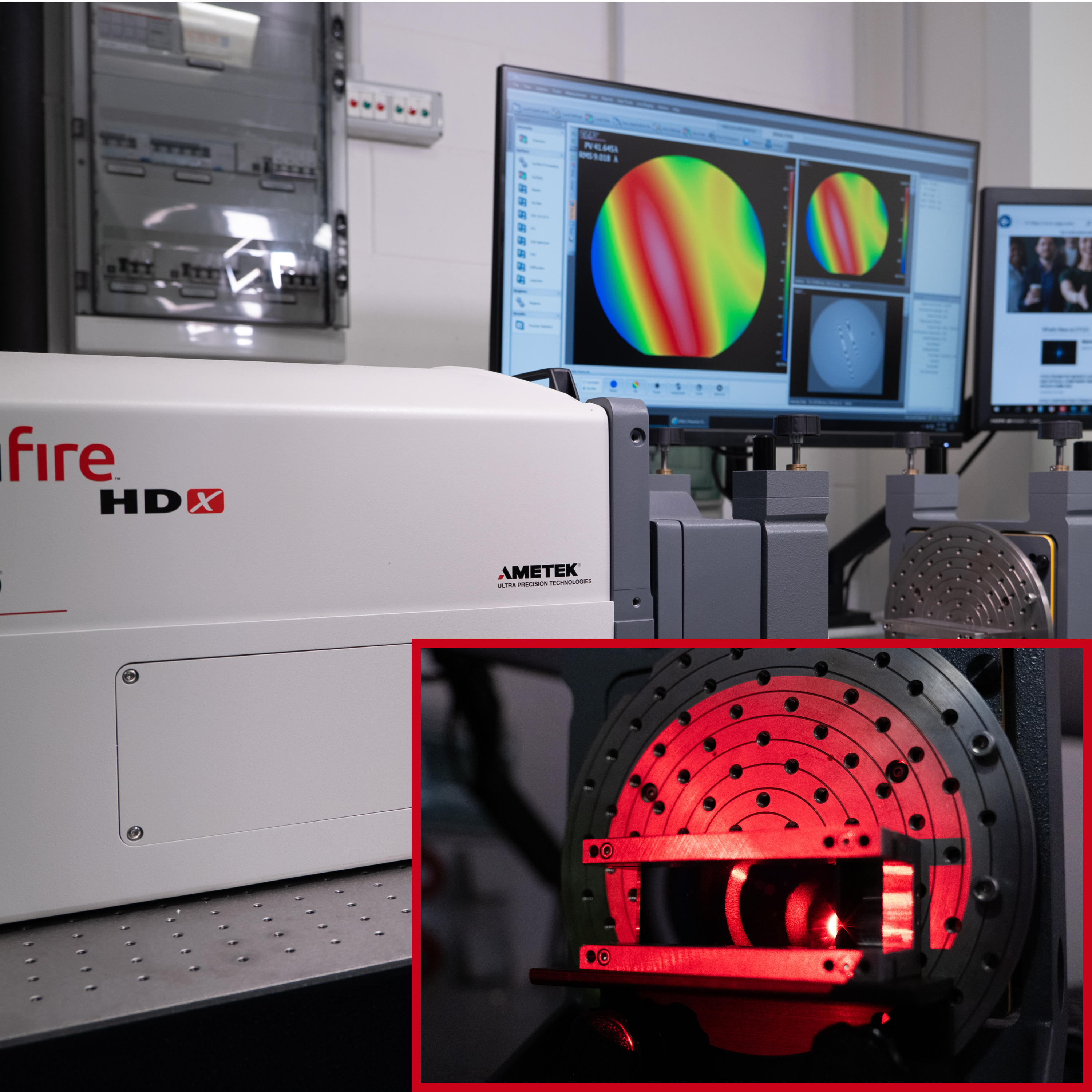

In this article, we'll explore what laser interferometry is, its principles and how it can revolutionize your approach towards accurate measurements in your field. So let's dive right into understanding the basics of Laser Interferometry for Precision Engineering! Fizeau laser interferometry is a highly precise and powerful measurement technique used in a variety of fields such as metrology, engineering, and materials science. It is named after Armand Fizeau, a French physicist who first developed the principle of interference in the 19th century. In Fizeau laser interferometry, a laser beam is split into two parts. One part is directed towards the object being measured, while the other part is directed towards a reference mirror. The light waves from both paths are then recombined and interference patterns are observed and analyzed to determine the surface profile of the object. The process of recombining the light waves results in either constructive or destructive interference, depending on the path length difference between the two beams. By measuring the intensity of the resulting interference pattern, it is possible to determine the surface profile of the object being measured. Fizeau laser interferometry has a number of advantages over other measurement techniques. For example, it is non-contact, which means that the object being measured is not touched or disturbed in any way during the measurement process. In addition, Fizeau laser interferometry is extremely precise, capable of measuring surface profiles to within a few nanometers. This level of accuracy makes it an essential tool in many industries, including semiconductor manufacturing, aerospace engineering, and optics production. Fizeau laser interferometry is also highly adaptable and can be used to measure a variety of surface profiles. For example, it can be used to measure the flatness of semiconductor wafers, the surface roughness of metal components, and the curvature of lenses and mirrors. Ametek-Zygo Fizeau interferometersAt our laboraoty we are proud users of a Zygo HDX interferometer. Among the most common applications of this tool it is worth to recall:

ConclusionWe have explored the basics of laser interferometry for precision engineering, showing how this method utilizes interference patterns to measure objects accurately. This cutting-edge technology is being used by engineers and manufacturers around the world to create more complex parts with greater accuracy than ever before. With its ability to produce accurate measurements quickly, laser interferometry has become an invaluable tool in modern manufacturing processes - allowing businesses and research to reach cutting-edge results. |

|